Problem: There is a model shift happened while printing the two-color model Reason: There is something wrong with the core board setting Solution: The right extruder should be as the …

- [PDF]

Dia 1 - 3dhubs.com

How do plastic properties degrade in product life Towards the right FDM filaments = value chain approach! Boost mechanical properties Product responsibility: REACH & RoHS Certifications …

//该项配置是为了了保护你的设备,避免加热温度过高高产生生以外。但不不能防止止温度传感器器非非正常工工作的情况。// 你应该使用用MINTEMP选项来保证温度传感器器短或损坏时的设 …

Notwithstanding any information provided by 3D Systems or its affiliates, the customer remains fully responsible for determining which federal, state, or local laws or regulations, or industry …

Same Day. Strong Parts. Designed to strong, high quality, uncompromised parts, Markforged 3D PrintersTM are the world’s first 3D printers capable of printing continuous carbon fiber, …

With the part selected, go to print > Send to 3D printer service. Click on options and make sure that units are set to mm and resolution is set to High. Then click “OK” and save the .stl. If a …

Introduction This Kit discusses how to select the right manufacturing process for metal parts by comparing CNC and Additive Manufacturing (AM) technologies. A step-by-step summary is …

Finally, put back red cover and connect right extruder to E1 with flat wire. If you want to print with two extruders simultaneously, please level the bed by touch screen first. Choose “SET” → …

After printing a test print and seeing a layer shift you can then inspect your marks and see which pulley(s) have moved. It is likely that the pulley(s) that need tightening are those connected to …

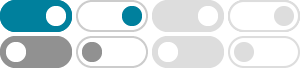

// A dual x-carriage design has the advantage that the inactive extruder can be parked which // prevents hot-end ooze contaminating the print. It also reduces the weight of each x-carriage // …